How to Choose the Best Parts for LPBF Printing?

Laser Powder Bed Fusion (LPBF) is a metal 3D printing technology that can create

complex & high-performance parts for various applications. However, LPBF is NOT a

one-size-fits-all solution for every part and every industry!

Beware - some parts may be more suitable for LPBF than others, depending on

factors such as geometry, material, function, quality, and cost.

What are the benefits of LPBF Printing?

1. Design Freedom

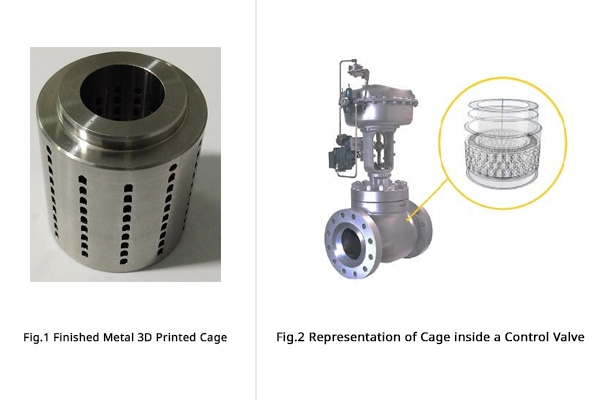

LPBF printing can create parts with complex shapes, internal features, lattice

structures, and topology optimization that are difficult or impossible to

produce with conventional manufacturing methods! This opens a world of:

- New Functionalities

- Improved Performance

- Reduced Weight and

- Material Usage

3. Part Consolidation

LPBF printing can create parts with integrated or reduced components that

eliminate the need for assembly, welding, or fastening. This can:

- Reduce Part Count

- Simplify Supply Chain

- Enhance Reliability

- Increase Durability

4. Customization

LPBF printing can create parts with personalized features that meet the

specific needs or preferences of the end users. This can enable:

- Mass Customization

- On-demand Production

- Customer Satisfaction

How to choose the best parts for LPBF printing?

To choose the best parts for LPBF printing, it is important to consider the following

factors:

1. Geometry

The geometry of the part affects its printability and quality in LPBF printing. Parts

that are more suitable for LPBF printing are those with:

- Complex Shapes

- Internal Features

- Lattice Structures, or

- Topology Optimization

than those with simple shapes or external features. Parts with overhangs,

bridges, hollows, or thin walls may require support structures or special process

parameters to avoid distortion or defects in LPBF printing.

2. Material

The material of the part affects its availability and cost in LPBF printing. Parts

with materials that are compatible with LPBF printing are more suitable than

parts with materials that are incompatible or unavailable. Parts with materials

that have high melting point, low thermal conductivity, high thermal expansion

coefficient, or high viscosity may require higher laser power or lower scan speed

to achieve full melting or avoid balling in LPBF printing.

3. Function

The function of the part affects its performance and quality requirements in LPBF

printing. Parts with critical functions that require:

- High Strength

- Stiffness

- Fatigue Resistance

- Corrosion Resistance, or

- Wear Resistance

are more suitable for LPBF printing than parts with non-critical functions that

require low strength, flexibility, ductility, or aesthetics. Parts with critical

functions may also require higher density, lower porosity, lower roughness, or

higher accuracy in LPBF printing.

4. Quality

The quality of the part affects its acceptance criteria and inspection methods in

LPBF printing. Parts with high quality standards that require strict dimensional

accuracy, surface quality, mechanical properties, or functionality are more

suitable for LPBF printing than parts with low quality standards that require

loose dimensional accuracy, surface quality, mechanical properties, or

functionality. Parts with high quality standards may also require more post-processing steps such as heat treatment, surface finishing, machining, or testing

in LPBF printing.

5. Cost

The cost of the part affects its profitability and feasibility in LPBF printing. Parts

with high value-added features that justify the high investment and running costs

of LPBF printing are more suitable than parts with low value-added features that

do not justify the high investment and running costs of LPBF printing. Parts with

high value-added features may include:

- Complex Geometries

- Customized Features

- Integrated Components, or

- Improved Performance in LPBF printing

Choose parts wisely with Intech’s custom software!

Intech’s in-house software can analyse a portfolio of manufactured parts and

recommend a list with which to begin your Additive Manufacturing journey.

Intech’s end to end expertise ensures that we provide first time right support from

part identification to designing a part.

If you are interested in learning more about how to choose the best parts for LPBF

printing, contact us today on marketing@intechadditive.com.

I hope this blog post has helped you understand how to identify the right set of parts

to begin your additive journey!

Happy Printing!