Key Considerations / Objectives

- To enhance the heat transfer from the electronic component.

- To reduce the size of the heat sink without affecting the heat transfer efficiency.

- To enhance the heat dissipation by incorporating biomimicry in design.

This article will discuss design practices that ensure better thermal management for electronic circuits, including some common methods for removing excess heat using custom-designed heat sinks with passive cooling.

Additive manufacturing (AM) has opened new avenues for novel heat sink designs that can be optimized for flow and conduction considerations. Besides the component itself, the resistance of the electrical connections and copper traces contribute to some generation of heat. To avoid circuit malfunctions, custom designs for heat sinks manufactured additively, aim at producing electronics that operate and remain within safe temperature limits.

Heat sinks are a kind of heat exchanger used for cooling electronic components. They are widely used due to the simplicity of fabrication, low cost, size, and reliability of heat dissipation. In the last decades, a lot of effort has gone into miniaturizing electronic devices incorporating developments in micro-and nano-technologies. Heat dissipation techniques for electronics and enhancing the thermal performance of heat sinks are thus increasingly relevant. The heat removal from heat sinks can be enhanced by modifying the characteristics of either the solid or the fluid domain. The miniaturization of electronic systems throws up the additional challenge of designing efficient systems that can operate in limited spaces. An effective way to enhance heat transfer is geometry modification which is the focus of this article.

In this article, non-traditional geometries are optimized using nTopology to address the above challenges and make the designs employing geometries that are functional and suitable for metal additive manufacturing.

We focus only on the enhanced surface area and the surface roughness to improve the design of the heat sinks. The heat transfer coefficient and the surface roughness are correlated, and the convective heat transfer coefficient is higher when the surface is rough.

Using nTopology provides an interesting design optimization route for the heat sinks manufactured using LPBF (laser powder bed fusion) technology. In the present study, all samples are made of AlSi10Mg and copper alloy.

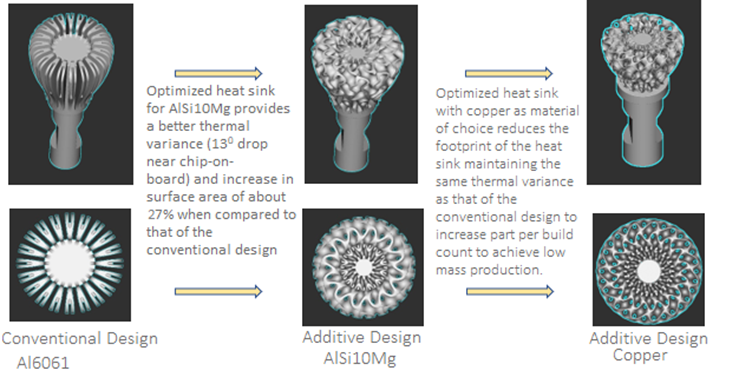

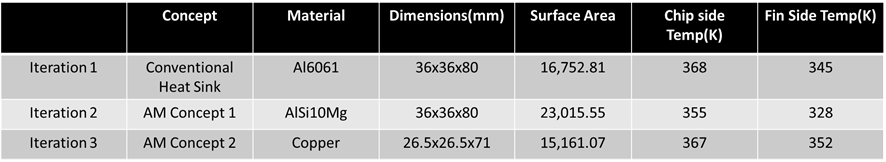

Topology optimized designs for passive cooling of light-emitting diode (LED) lamps are investigated through extensive numerical parameter studies. The designs are optimized for vertical orientations and are compared to a lattice-fin design as well as a simple commercial fin design. Such parts are ideal for low mass production using AM. The optimization favors placing material at the outer boundaries of the designed part, for more heat dissipation.

One such example is the heat sink of LED in Head Lights is made compact through AM design without affecting the performance of the heat sink. The efficiency can be still more increased by increasing the surface roughness in addition to the above results. The temperature gradient meets the requirement of the heat sink transfers and the temperature remains marginally equal to the conventional method.

Fig 1. nTopology design for higher efficiency of the heat sink for LED cooling

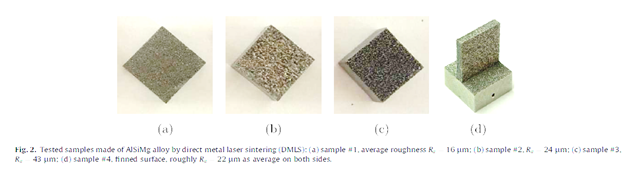

Forced air heat transfer enhancement has been extensively explored and many augmentation techniques have been proposed for surfaces with arrays of protrusions, metal foams, and artificial surface roughness. By artificial surface roughness, we mean any surface patterning with enough regularity and purposely designed to enhance heat transfer. The resulting heat transfer enhancement of the scale roughened surface is surprisingly good compared to rib roughened and dimpled surfaces. This proves that there is still room for improving the heat transfer by inducing appropriate variations in the surface finish.

Fig 2. Topology design optimization helps to increase the surface roughness to enhance the heat transfer ratio. Image courtesy by Elsevier

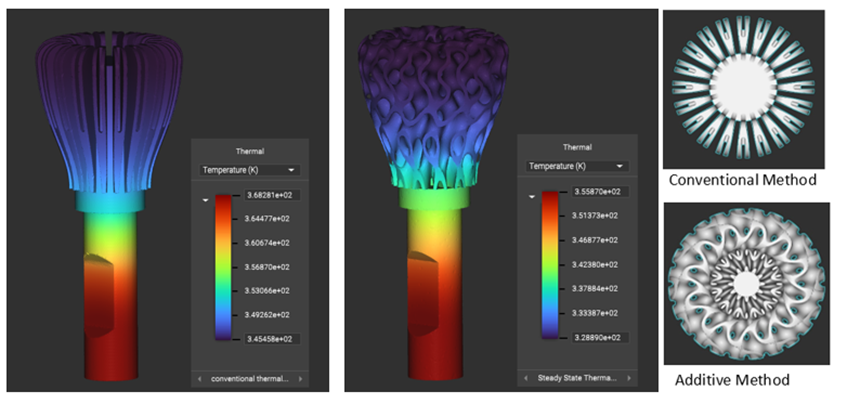

Performing a thermal analysis establishes how the components will behave at different temperatures and conditions. The analysis results and the simulation techniques aim to help better manage the heat dissipation in electronic circuits. Factors to consider when deciding on a cooling mechanism include the package properties of the semiconductor, required operating conditions and heat dissipation properties. This information is usually available from the manufacturer’s datasheet.

Natural convection cooling is adequate for electronic components with small amounts of heat dissipation. However, for cooling components with excess heat generation, a combination of various cooling techniques may be required that incorporate heat sinks along with heat pipes and fans.

Fig 3. Analysis image showing temperature gradient in electronic component.

In this article, we investigate the effect of surface roughness induced by LPBF along with an optimized design for convective heat transfer enhancement, in manufacturing flat and finned heat sinks for electronics cooling. The key benefits obtained from this approach are listed below.

The surface area in AM design with Aluminium material is enhanced up to 27% over the conventional design.

The thermal variance in AM design is up to 130C (drop near chip-on-board) over the conventional design.