What is the difference between Powder Metallurgy and Casting based traditional manufacturing techniques from an input raw material perspective?

Metal materials are used in wide range of applications, from manufacturing tiny pins to building giant rockets. Manufacturing products out of metal involves the material to undergo numerous processes. The processability of the metal plays an important role in deciding its feasibility for the specific application.

Metal materials are generally processed from two forms – powder and bulk. Each has its own advantages and limitations, handling requirements and manufacturing techniques.

Powder Metals

Powder metal refers to finely divided metal particles of particle size ranging from microns to millimetres. Powders react to its surrounding very rapidly due to its increased surface area. Special attention is needed while handling metal powders as they are sensitive to moisture, highly reactive and prone to oxidation which can deteriorate its processability. Metal powders can be made of single metal or a combination of multiple metals depending on the requirement and application. Powder metals can be processed through some unique techniques:

- Powder Metallurgy

- Metal Injection Moulding

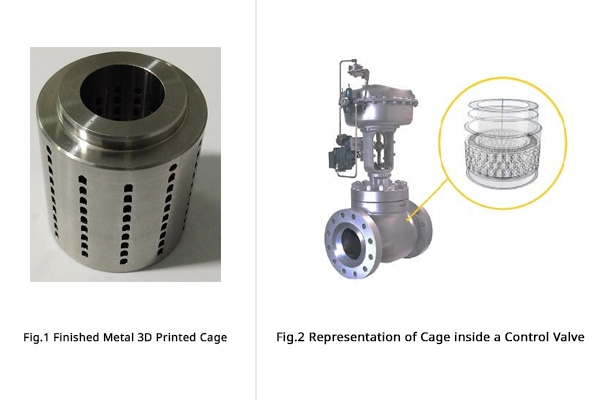

- Additive Manufacturing (3D Printing)

These processes allow metal powders to be manufactured for a wide range of applications in different sectors like automotive, aerospace, medical and consumer electronics.

Bulk Metals

Bulk metal refers to the metal in its solid and dense form, like sheets, bars, billets, or ingots. Bulk metals are widely used across the industries because of its easy availability and reliability. Bulk metals are generally processed through conventional manufacturing techniques:

- Casting

- Forming and Machining

- Welding and Joining

These processes allow bulk metals to be manufactured for a wide range of applications giving a strong and reliable component. Processing bulk metals only lack in manufacturing components having intricate designs.

Summary

To summarize, powder metals and bulk metals have distinct processability and production scaling due to the manufacturing techniques used. Both the forms of metals have their own applications, advantages, and limitations. It is impossible that either one of the forms can replace the other because of their unique processing characteristics.

Of course, they can complement each other by replacing the limitation of one with the strength of other. For example, rapid prototyping can be used to make moulds and dies of intricate shapes for processing bulk metals. In this way, bulk metals can also be given complex shapes with the help of processed powder metals.