Additive manufacturing of hydraulic application components, like

hydraulic manifold block, End fittings, accessories, is a powerful alternative to

traditional manufacturing methods such as machining and casting. Additive Manufacturing

allows a much higher level of design freedom, part integration, to reduce weight and

improve the media flow paths with varied geometry shape and size (shape) of internal

channels for ideal flow by maintaining the structural integrity.

Hydraulic manifold blocks are crucial elements of hydraulic systems

and usually have a conventional compact, square design with multiple internal channels

in straight lines that enable them to control the fluid distribution of large machines

or systems in automotive or industrial safety equipment.

Conventional manufacturing of Hydraulic manifold block

The traditional manufacturing of hydraulic manifold blocks causes

very high machining costs with milling and drilling operations to create the internal

fluid channels that are in straight lines or angular lines leading to high costs and,

long lead time. (Which causes high machining costs.)

The challenges and disadvantages of traditional Hydraulic manifolds

- Abrupt angled junctions between flow paths can

cause flow stagnation with dead legs and an increase in hold-up volume resulting in

loss of flow efficiency.

- The edges create stresses which are not loosened

and cannot be removed while in operation.

- Dirt reservoirs are formed at areas with no fluid

flow causing damage to failure to the whole system.

- The waiting period for a new hydraulic manifold

block in case of failure leads to machine downtime losing a high rate of MHR.

Advantages for Printing in AM:

- Reduction in Build time

- Reduction in Material consumption

- Reduced post processing & support removal

- Increased Efficiency

- No leakage in operation

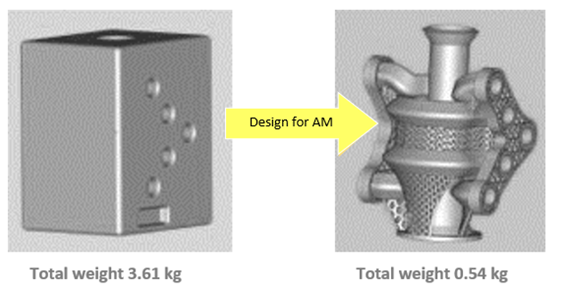

Intech Additive reduced the weight of the hydraulic manifold block from 3.61

to 0.51kg down by 3.10kg

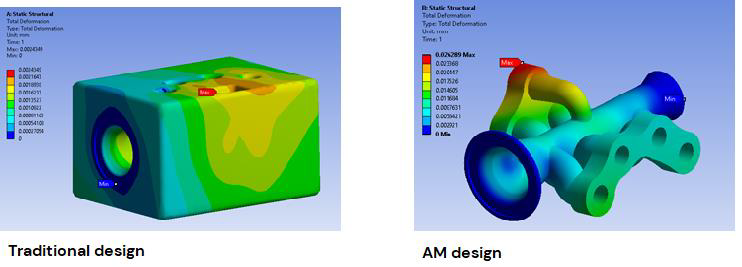

Improved flow efficiency

The horizontal holes are no longer needed, the fluid can now flow around the corner and

is not disturbed by corners and edges.

- Homogeneous wall thickness

- Design flexibility

- No Leakage risks

- No stress risks

- Smooth channels for optimal flow

- Light weight

- Improves energy efficiency and

reliability

The final hydraulic manifold block redesigned in additive

manufacturing.

Design for Additive Manufacturing (DfAM)

With a more complex hydraulic manifold block, it is possible to adjust the fluid

channel lengths to each other. AM provides a flexible design option for shorter

channel flow paths to avoid losses against the longer fluid channel and less risk of

leakage. Shorter channels and no sharp corners mean higher energy efficiency.

Advantages of Design for AM

- The wall thicknesses can be

adjusted as required.

- Rapid design repetitions and no

tooling costs.

Optimize the flow path with AM

- AM allows users more time to

change the design decision.

- Total flexibility and adjust the

design at any time.

About the Author

Gregg Profozich

Gregg Profozich is a manufacturing, operations and technology executive who believes that

manufacturing is the key creator of wealth in the economy and that a strong manufacturing

sector is critical to our nation’s prosperity and security now, and for future generations.

Across his 20-year plus career in manufacturing, operations and technology consulting, Mr.

Profozich helped manufacturing companies from the Fortune 500 to the small, independents

significantly improve their productivity and competitiveness.